Ethylene Dichloride (EDC)

Product Details:

- Appearance Clear, colorless liquid

- Molecular Weight 98.96 g/mol

- Odour Chloroform-like, sweet odor

- Density 1.252 Gram per cubic centimeter(g/cm3)

- Ph Level Neutral

- Solubility Soluble in most organic solvents; slightly soluble in water

- Storage Instructions Store in cool, dry, well-ventilated area, away from heat and direct sunlight; tightly closed container

- Click to View more

Ethylene Dichloride (EDC) Price And Quantity

- 1Ton Piece

- 40.00 - 80.00 INR

Ethylene Dichloride (EDC) Product Specifications

- 24 months from date of manufacture

- 107-06-2

- Primarily in chemical and polymer industry

- 98.96 g/mol

- Used in production of vinyl chloride monomer for PVC, organic synthesis, solvent applications, degreasing, and extraction processes

- Organic Chemical Compound

- Chloroform-like, sweet odor

- Ethylene, chlorine

- 1.252 Gram per cubic centimeter(g/cm3)

- Store in cool, dry, well-ventilated area, away from heat and direct sunlight; tightly closed container

- Soluble in most organic solvents; slightly soluble in water

- Clear, colorless liquid

- Ethylene Dichloride

- Liquid

- 99% min

- 24 months

- Industrial Grade

- As per industrial requirement/procedure

- Neutral

- 1,2-Dichloroethane, EDC

Ethylene Dichloride (EDC) Trade Information

- Cash Advance (CA), Letter of Credit (L/C), Telegraphic Transfer (T/T), Letter of Credit at Sight (Sight L/C), Cash in Advance (CID), Cheque

- 30 Piece Per Day

- 15-30 Days

- Yes

- Contact us for information regarding our sample policy

- Barrel

- Western Europe, Central America, South America, Australia, Eastern Europe, North America

- All India

Product Description

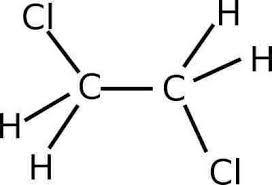

Ethylene Dichloride (EDC) is a colorless industrial compound with chloroform like odor. It is highly flammable and irritant in nature hence it is advised to handle it with extra care. The chemical formula of this compound is C2H4Cl2 with an average molecular weight of 98.96 grams per mol. The offered Ethylene Dichloride (EDC) has a boiling point of 84 degrees Celsius. Customers can get this corrosive chemical in large volume with an assurance of fast and safe delivery.

Versatile Industrial Applications

Ethylene Dichloride finds primary use in manufacturing vinyl chloride monomer for PVC, as well as in organic synthesis, industrial cleaning, and extraction processes. Its effectiveness as a solvent and degreaser makes it a versatile chemical for many applications in the polymer and chemical sectors.

Safe Handling and Storage Guidelines

Due to its toxicity and flammability, EDC should be handled with proper industrial procedures. Store it in cool, well-ventilated areas, away from heat or direct sunlight, and in tightly sealed containers. Following these guidelines ensures product stability and prolongs shelf life to 24 months.

Physical and Chemical Properties

EDC is a clear, colorless liquid with a neutral pH and a density of 1.252 g/cm. It has a low melting point (-35.7C), a moderate boiling point (83.5C), and is slightly soluble in water but readily dissolves in most organic solvents. Its sweet, chloroform-like aroma is distinctive.

FAQs of Ethylene Dichloride (EDC):

Q: How should Ethylene Dichloride (EDC) be safely stored and handled?

A: EDC must be stored in a cool, dry, well-ventilated area, away from sources of heat, open flames, or sunlight. Containers should be tightly closed, and standard industrial safety protocolsincluding proper ventilation and personal protective equipmentshould always be followed to reduce exposure risks.Q: What are the primary industrial applications of Ethylene Dichloride?

A: EDC is mainly used in producing vinyl chloride monomer for the manufacture of PVC. Additionally, it serves in organic synthesis, as a solvent in industrial cleaning, degreasing, and extraction operations, leveraging its chemical properties for versatile industrial use.Q: When is it recommended to use Ethylene Dichloride in chemical processes?

A: EDC should be used according to specific industrial procedures, typically during the synthesis of vinyl chloride or as indicated for solvent and extraction applications. Its use depends on process requirements and should be carried out in controlled environments with appropriate safety measures.Q: Where is Ethylene Dichloride (EDC) commonly sourced and supplied?

A: EDC is exported, manufactured, and supplied globally, with India being a significant producer and supplier. It is typically distributed in drums, ISO tanks, or bulk containers to various chemical and polymer industry sectors.Q: What makes Ethylene Dichloride (EDC) beneficial in solvent and extraction applications?

A: EDCs high purity, excellent solvency characteristics, and ability to dissolve a wide range of organic substances make it especially effective in solvent and extraction roles. Its chemical stability under normal storage conditions ensures reliable performance over a 24-month shelf life.Q: How hazardous is Ethylene Dichloride, and what precautions are necessary?

A: Ethylene Dichloride is classified as toxic and possibly carcinogenic. It is harmful if inhaled, ingested, or if it contacts skin, and poses dangers to aquatic life. Handling requires proper PPE, adequate ventilation, and strict adherence to safety protocols to prevent exposure.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Solvent' category

Parent Company-

REE ATHARVA LIFE SCIENCE PVT. LTD.

Plot no-5178 GIDC Ankleshwar

Sister Concern Company-

1. ATHARVA ENTERPRISES

Plot No- J-5231 GIDC, Ankleshwar.

2. RANKE ATHARVA ENTERPRISE PVT LTD

Plot No.-5157&5158 GIDC, Ankleshwar.

|

REE ATHARVA LIFESCIENCE PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese