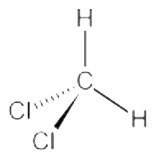

Methylene Di chloride (MDC)

Product Details:

- Molecular Weight 84.93 g/mol

- Ph Level Neutral

- Appearance Colorless transparent liquid

- Density 1.32 Gram per cubic centimeter(g/cm3)

- Solubility Slightly miscible with water; fully miscible with most organic solvents

- Chemical Name Methylene Di chloride

- Other Names Dichloromethane, DCM, Methane dichloride

- Click to View more

Methylene Di chloride (MDC) Price And Quantity

- 40.00 - 80.00 INR

- 1Ton Piece

Methylene Di chloride (MDC) Product Specifications

- Colorless transparent liquid

- Liquid

- Rapid (Evaporates quickly at room temperature)

- Neutral

- 2 years

- 1.32 Gram per cubic centimeter(g/cm3)

- Slightly miscible with water; fully miscible with most organic solvents

- Within shelf life from date of manufacturing

- 84.93 g/mol

- Industrial

- Dichloromethane, DCM, Methane dichloride

- Methylene Di chloride

- Solvent

- Direct use as industrial solvent or chemical intermediate

- Paint remover, Degreaser, Adhesive manufacture, Aerosol formulations, Pharmaceutical processing

- 99.9%

Methylene Di chloride (MDC) Trade Information

- Letter of Credit (L/C), Telegraphic Transfer (T/T), Letter of Credit at Sight (Sight L/C), Cash in Advance (CID), Cheque, Cash Advance (CA)

- 30 Piece Per Day

- 15-30 Days

- Yes

- Contact us for information regarding our sample policy

- Barrel

- Australia, Eastern Europe, Western Europe, Middle East, Central America, Africa, South America, Asia, North America

- All India

Product Description

We commenced our business operation in the year 2007 with a motto to offer our clients an unparalleled range of Methylene Di Chloride. These colorless liquids are mainly used as a solvent in paint, adhesive and coatings. In order to formulate Methylene Di Chloride, our experts uses quality approved components and modern technology at our hygienic facility. As a quality centric organization, we ensure quality of our solvents at the mean time offer them at a nominal price.

Features:

- Perfect chemical composition

- Longer shelf life

- Pure

Specifications:

| MDC Pure | |

| Purity | 99.5 % |

| Gravity | 1.31 |

| Packing | 250 kg |

| MDC | |

| Purity | 90 to 97 % |

| Gravity | 1.3 |

| Packing | 250 kg |

Versatile Industrial Applications

Methylene Di chloride serves a crucial role in several industries thanks to its potent solvent properties. It is commonly used as a paint remover, degreasing agent, and in the production of adhesives and pharmaceuticals. Its rapid evaporation and high purity make it ideal for processes where quick drying and residue-free finishes are essential.

Safe Handling and Storage Guidelines

To maximize the shelf life of Methylene Di chloride, store it in tightly sealed containers away from direct sunlight or extreme temperatures. This ensures the liquid retains its purity and effectiveness over the recommended two-year period. As with all chemicals, adhere to safety protocols during handling and usage.

FAQs of Methylene Di chloride (MDC):

Q: How is Methylene Di chloride typically used in industrial settings?

A: Methylene Di chloride is directly applied as a solvent or chemical intermediate during paint removal, degreasing, adhesive production, aerosol formulation, and in some pharmaceutical processes due to its rapid evaporation and strong solvency.Q: What are the main benefits of using Methylene Di chloride in manufacturing?

A: Its primary benefits include effective cleaning, quick drying, high purity (99.9%), and compatibility with most organic solvents, making it a preferred choice for producing residue-free surfaces and facilitating efficient processing steps.Q: When should Methylene Di chloride be used within its shelf life?

A: It should be used within two years from its manufacturing date to ensure optimal performance and prevent degradation, as recommended by suppliers and manufacturers.Q: Where is Methylene Di chloride most commonly applied?

A: It is widely applied across paint and adhesive industries, degreasing operations, aerosol product formulations, and pharmaceutical manufacturing units, particularly throughout India.Q: What is the proper process for handling and storing Methylene Di chloride?

A: Store the liquid in a tightly sealed container in a cool, well-ventilated area, away from sunlight and incompatible substances. Always use appropriate protective equipment and follow safety guidelines during handling.Q: How does Methylene Di chloride interact with water and other solvents?

A: It is only slightly miscible with water but fully miscible with most organic solvents, which allows it to be easily integrated into numerous industrial processes requiring solvent mixing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Industrial Solvent' category

Parent Company-

REE ATHARVA LIFE SCIENCE PVT. LTD.

Plot no-5178 GIDC Ankleshwar

Sister Concern Company-

1. ATHARVA ENTERPRISES

Plot No- J-5231 GIDC, Ankleshwar.

2. RANKE ATHARVA ENTERPRISE PVT LTD

Plot No.-5157&5158 GIDC, Ankleshwar.

|

REE ATHARVA LIFESCIENCE PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese