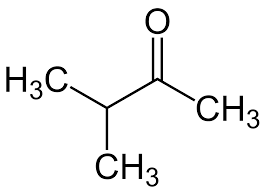

Isobutyl Methyl Ketone

Product Details:

- Molecular Weight 100.16 g/mol

- Appearance Clear, colorless liquid

- Odour Mild, sweet odor

- Solubility Slightly soluble in water, miscible with most organic solvents

- Chemical Name Isobutyl Methyl Ketone

- Classification Ketone solvent

- Type Industrial Organic Solvent

- Click to View more

Isobutyl Methyl Ketone Price And Quantity

- 40.00 - 80.00 INR/Piece

- 1Ton Piece

Isobutyl Methyl Ketone Product Specifications

- Liquid

- Isobutyl Methyl Ketone

- Solvent for resins, lacquers, nitrocellulose, extraction process

- 99.0%

- 100.16 g/mol

- 24 Months

- Acetone, Isopropanol

- Fast evaporating (Specific depending on application)

- Clear, colorless liquid

- Mild, sweet odor

- Industrial Organic Solvent

- Coatings, adhesives, chemical intermediates, extraction, paints

- Ketone solvent

- Slightly soluble in water, miscible with most organic solvents

- 2 years from manufacturing date when stored properly

- Mixing/Blending with formulations or direct application as solvent

Isobutyl Methyl Ketone Trade Information

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- 30 Piece Per Day

- 15-30 Days

- Yes

- Contact us for information regarding our sample policy

- Barrel

- Eastern Europe, Africa, South America, Australia, Asia, Central America, North America

- All India

Product Description

Being an experienced firm, we are capable of meeting the quality MethylIsobutyl Ketone needs of our clients. Owing to characteristics ike purity and precise composition, these are used as a solvent for gums,resins, paints, varnishes, lacquers, and nitrocellulose. In addition, our MethylIsobutyl Ketone is processed by using quality compounds at our hygienic facility, in compliance with the international quality of stands and norm. We offer these solvents to the clients at a reasonable price.

Features:

- High efficacy

- Eco-friendly

- Longer shelf life

Specifications:

| Purity | 99.5 % |

| Moisture | 0.1 % |

| Packing | 160 kg |

Exceptional Solvency and Fast Drying

Isobutyl Methyl Ketone is renowned in the chemical industry for its strong solvency power and rapid evaporation rates. These features make it a preferred choice for manufacturers requiring quick-drying formulations in paints, adhesives, and coatings. Its ability to dissolve a wide range of organic compounds ensures smooth processing and effective blending in industrial applications.

Versatile Applications Across Industries

Beyond its primary use as a solvent in coatings and adhesives, Isobutyl Methyl Ketone serves as a reliable option for extraction processes and as a chemical intermediate. Its versatility is enhanced by compatibility with most organic solvents, supporting diverse manufacturing needs, including paints production and resin-based formulations.

FAQs of Isobutyl Methyl Ketone:

Q: How is Isobutyl Methyl Ketone typically used in industrial processes?

A: Isobutyl Methyl Ketone is commonly used by mixing or blending it with various formulations or applying it directly as a solvent. Its fast evaporation rate makes it particularly suitable for extraction processes, coatings, adhesives, and nitrocellulose-based products.Q: What are the primary benefits of using Isobutyl Methyl Ketone as a solvent?

A: The main advantages include rapid drying, high purity (99.0%), excellent solvency for resins and lacquers, and compatibility with a broad range of organic solvents. These properties help enhance process efficiency and product performance across multiple industries.Q: When should Isobutyl Methyl Ketone be used within a products lifecycle?

A: Isobutyl Methyl Ketone is best used during the formulation and blending stages of manufacturing coatings, adhesives, or paints. Its properties allow for fast evaporation and efficient solubilization of key ingredients.Q: Where is Isobutyl Methyl Ketone primarily applied?

A: This solvent finds major application in industrial settings such as paint and coating factories, adhesive production units, and chemical processing plants throughout India and globally. Its also utilized in extraction and synthesis tasks within laboratories.Q: What is the expected shelf life and how should Isobutyl Methyl Ketone be stored?

A: The shelf life of Isobutyl Methyl Ketone is 24 months from the manufacturing date, provided it is kept in tightly sealed containers, away from direct sunlight, heat, and sources of ignition. Proper storage ensures it retains its clarity, effectiveness, and purity.Q: How is Isobutyl Methyl Ketone manufactured?

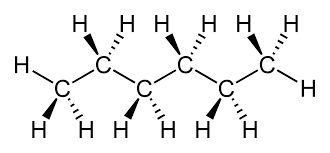

A: This solvent is synthesized using acetone and isopropanol as key raw materials through a controlled chemical process to achieve the desired purity and solvent characteristics.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Industrial Solvent' category

Parent Company-

REE ATHARVA LIFE SCIENCE PVT. LTD.

Plot no-5178 GIDC Ankleshwar

Sister Concern Company-

1. ATHARVA ENTERPRISES

Plot No- J-5231 GIDC, Ankleshwar.

2. RANKE ATHARVA ENTERPRISE PVT LTD

Plot No.-5157&5158 GIDC, Ankleshwar.

|

REE ATHARVA LIFESCIENCE PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese